Technocleaner coldset, the reference for 20 years

The global newspaper industry is changing. Technological developments and revenue erosion are forcing publishers and print centres to rethink their production equipment, especially their presses. It is imperative to restructure and lower costs. The Technocleaner is an essential tool in optimizing the operation of a newspaper press.

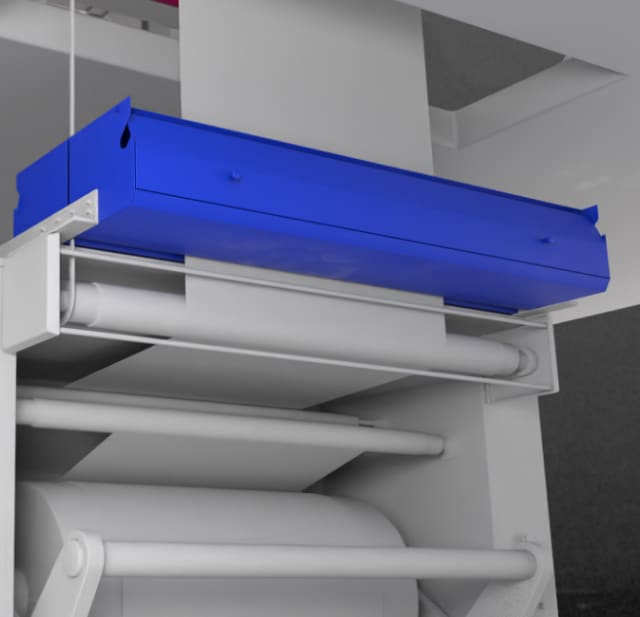

The Technocleaner process uses the paper web to perform a global washing of the newspaper web press.

The washing agent is sprayed directly onto each side of the paper web.

The friction of the web with blankets, cylinders and rollers allows for a short and effective automatic washing process.

1000+

Equipped webs

coldset and heatset

100+

Printers

users

1

System

per tower and per web

22

Countries

with Techniweb installations

benefits

A more cost-effective press

-

- Better management of the shifts

- Increase in productivity

- Reduced maintenance and spare parts costs

- Reduction of waste disposal and destruction cost

- Lower cost in consumables

- Lower cost in spare parts

benefits

Quality and safety

-

- Better print quality

- Operators safety improvement

- Lower paper waste

What are the different stepsto install your Techniweb solution?

We have been using the Technocleaner since 2005 on our Wifag OF370 presses to replace very heavy brush systems for maintenance and spare parts. Over the years the Technocleaner has given us the possibility to wash blankets, inking and dampening units as well as paper runs with very low maintenance costs compared to other technologies. This system is very reliable and has a remarkable lifetime, making it an excellent investment.

TECHNICAL APPLICATION

100% modular cleaning

Blankets

Washing is carried out at the end of the print run by direct contact between the paper, the washing agent and the blankets. This phase is very short with a minimum of paper waste.

Common impression

cylinders

Together with blankets, common impression cylinders are cleaned by direct contact, whether they are 9- or 10-cylinder units.

Inking and

dampening rollers

Inking and dampening rollers are cleaned by contact via the offset plate and print functions control through the Technocleaner/press interface.

Web leads

Web path rollers/turn bars/formers are cleaned by direct contact with the end of production wash or a specific program.

Plates

Plates are cleaned by direct contact at the same time as blankets and common impression cylinders.

Blankets and plates

in waterless offset

This is one of the big advantages of the Technocleaner used in dry offset. It allows a quick wash in 20 seconds at regular intervals without stopping the press and with a minimum waste of paper.

Blankets and Common impression cylinders

Second common impression cylinders can be washed during the run at regular intervals on 9 and 10 cylinder satellite units.

Blankets and dampening rollers in heatset

In semi-commercial application, Technocleaner provides a very short intermediate wash at regular intervals without stopping production.

Start-up assistance

A short start up wash is included in the automatic start-up sequence when requested with no additional waste of paper.

Web width changes wash

Technocleaner is designed to wash areas without paper during the web width changes when increasing pagination. The sequence is automatic and generates almost no paper waste. It allows a cleaning of the full web width with the appropriate method.

APPLICATION

Blankets

Washing is carried out at the end of the print run by direct contact between the paper, the washing agent and the blankets. This phase is very short with a minimum of paper waste.

Common impression

cylinders

Together with blankets, common impression cylinders are cleaned by direct contact, whether they are 9- or 10-cylinder units.

Inking and

dampening rollers

Ink and dampening are cleaned by indirect contact via the offset plate and function control via the Technocleaner/press interface.

Web leads

Web path rollers/turn bars/formers are cleaned by direct contact with the end of production wash or a specific program.

Plates

Plates are cleaned by direct contact at the same time as blankets and common impression cylinders.

Intermediate Wash

Blankets and plates in waterless offset

This is one of the big advantages of the Technocleaner used in dry offset. It allows a quick wash in 20 seconds at regular intervals without stopping the press and with a minimum waste of paper.

Blankets and Common impression cylinders

Second common impression cylinders can be washed during the run at regular intervals on 9 and 10 cylinder satellite units.

Blankets and dampening rollers in heatset

In semi-commercial application, Technocleaner provides a very short intermediate wash at regular intervals without stopping production.

Start-up Wash

Start-up assistance

A short start up wash is included in the automatic start-up sequence when requested with no additional waste of paper.

Web width changes washing

Technocleaner is designed to wash off-web parts during the web width changes on increasing pagination. The sequence is automatic and generates almost no paper waste. It allows a cleaning of the entire web width with the appropriate method.

APPLICATION

A solution which isdesigned for your press

Any type of blanket

-

- Classic Blanket

- Metal back blanket

- Sleeve blanket

All press widths

-

- Single width: AB

- Double width: ABCD

- Triple width: ABCDEF

Any kind of press

-

- Blanket/blanket

- Satellite 9 and 10 cylinders

- Waterless towers

- Heatset / Coldset

All types of paper

-

- 36-45 gsm

- 45 gsm

- Coated

- LWC