Blanket washing costsreduction oncommercial presses

The commercial printing business is very heavily impacted by the erosion of margins and volumes.

It is a highly competitive sector that is facing a significant concentration of production facilities.

In this context, it is essential to lower production costs by all means.

Technocleaner has many advantages to increase productivity, optimize costs and reduce paper waste.

1000+

Equipped webs

coldset and heatset

100+

Printers

users

1

System

per press and per web

22

Countries

with Techniweb installations

benefits

Benefits and savings

Higher productivity

-

- No manual washing

- 5 to 10 times fewer changes of cloth rolls

- Less web breaks

Paper saving

-

- 2 to 3 times less waste than brush/cloth system (150 to 300 revolutions)

Consumables savings

-

- 5 to 10 times less cloth consumption

- 0.5 to 1 litre of solvent per wash

Saving on maintenance and spare parts

-

- 5 to 10 times fewer brush/cloth washes

- No spare parts consumption

- No Technocleaner maintenance

Quality benefits

-

- Short washes at any time during the run

What are the different stepsto install your Techniweb solution?

We use the Technocleaner in addition to a cloth system which is expensive in consumables, heavy in maintenance and generates significant costs for the treatment of soiled cloth rolls. The Technocleaner is a simple, effective and economical washing system which cleans blankets, plates and also web leads.ICP Roto's teams have now definitively adopted this system as a complement to the one initially supplied with the press. Our feedback is therefore very positive: reduction in paper waste, reduction in consumables, reduction in press downtime (roller change, web breaks, etc.), working comfort are the undeniable advantages of the Technocleaner. The return on investment is immediate on our Waterless Cortina.

TECHNICAL APPLICATION

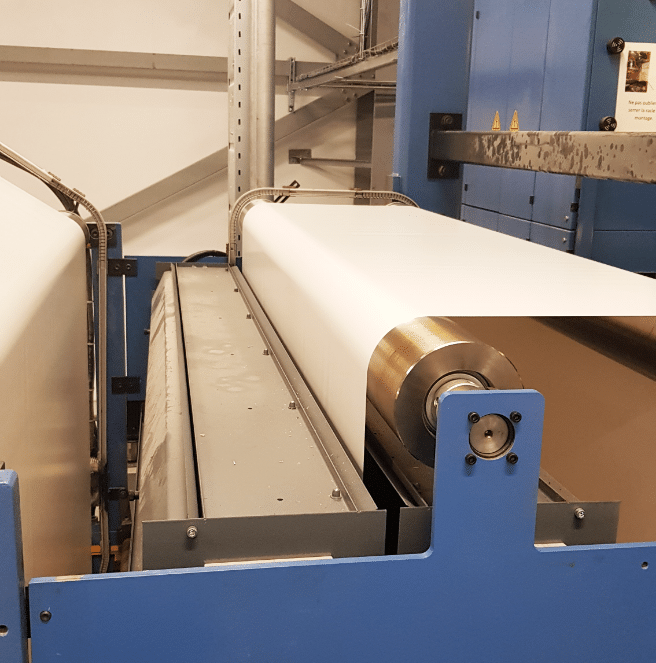

100% modular cleaning

Intermediate

blanket washing

Carried out for less than 20 seconds, at full or reduced speed, it allows an efficient blankets and dampening rollers cleaning. The wash cycle can be triggered automatically at flying splice with no additional waste of paper.

Blankets final wash

It is carried out automatically during the press run down.

Washing in combination

with a brush/cloth system

Technocleaner is a stand-alone system that works independently, but can also be used to improve the operation of a conventional system.

Start-up assistance

A wash program is available at crawl speed and during the speed-up sequence to assist start-up.

APPLICATION

Alternative andadditional system

-

-

- As a standalone system

-

As a replacement for a brush/cloth system or to eliminate manual washing. This application concerns presses which are not equipped with an automatic cleaning system, but also 8 to 32 pages presses equipped with a conventional system that is ageing and expensive to refurbish

-

-

- As an additional “Papersaver” system

-

On 48- to 96-pages presses with long runs, Technocleaner comes in addition to the existing brush/cloth washing system, which is expensive to use and not efficient enough.

Technocleaner is being used during the run with short intermediate washes at very regular intervals (splice) and the conventional system only at the end of the run.